Starting Lab Automation Integration Projects

Successfully operating laboratory automation systems requires agility, time management, and critical thinking to reduce errors when executing lab tasks. Labs of different sizes have increasingly realized that automating tasks, particularly repetitive and manual ones, increases productivity while improving turnaround times and enhancing staff safety.

By utilizing software for laboratories/scheduling software with widely used lab devices, labs can boost their throughput, increase the quality of their results and eradicate costs. However, there is no one-size-fits-all when starting lab automation integration projects, as some labs may only be prepared to integrate automation with a few steps. In contrast, other labs seek full lab automation. It’s essential to start with the basics when adopting integrated automation in your laboratory.

Automation Integration Basics

Irrespective of how complex or simple the integration or automation will be for lab automation integration projects, there are two key factors that lab technicians must remember to ensure success with these projects. For one, they must establish comprehensive plans for the short and long term. In addition, they should collaborate with quality vendors that understand both the current needs and long-term goals for the project.

Creating clear transition plans is an excellent place to start, pointing out the current state of the laboratory and visualizing what state you’re trying to take it going forward. The transition plans should naturally include analyzing new technologies or products, allowing you to pick vendors with the lab automation expertise to help you bring your integrated automation initiative to life.

Integrated Workflows And Devices

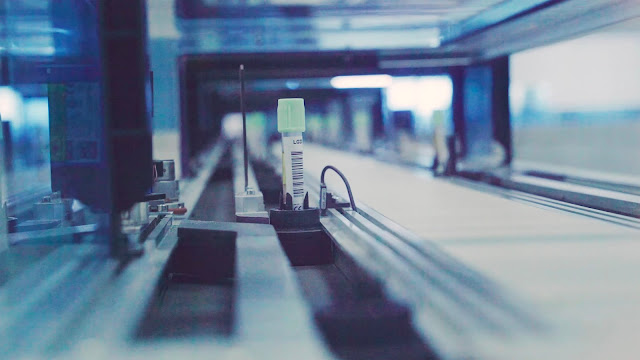

Before buying lab automation, you need to determine your workflow automation process. Automated liquid handlers will manipulate microtiter plates and automate all pipetting. However, adding more lab devices like a plate reader to the automated liquid handler will automate more of the workflow.

Additionally, you should execute a comprehensive integration plan to accommodate several standard lab devices and the software used with those devices. These devices include plate washers, images, transport devices, management devices, and temperature-controlled devices, among several others. Barcode readers, capping devices, and biocontainment enclosures may also be included.

Source- https://retisoft.com/starting-lab-automation-integration-projects/

Comments

Post a Comment