Choosing a Liquid Handler

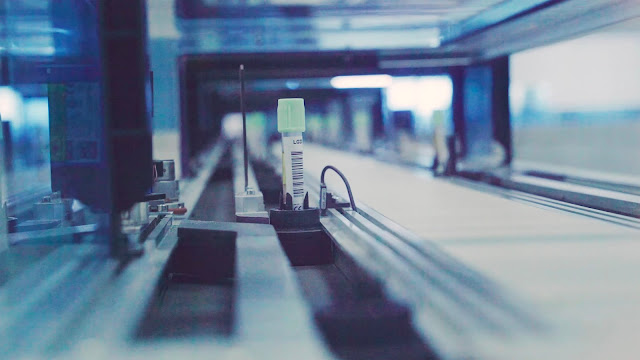

Liquid handling/pipetting is one of the most common laboratory processes. Thus, it is the procedure that is the most commonly automated when considering laboratory automation systems. Automating your liquid handling steps has many benefits. It improves precision, accuracy and consistency as well as minimizes human error, improves lab workflow, and reduces ergonomic injuries. Deciding on the needed components for a successful automated liquid handler will depend on your process and applications.

When Should You Consider Automating Liquid Handling?

- When sample/plate loads move from a few or dozen to hundreds/thousands

- When throughput needs move from 5-10 samples/plates per day to 20-100+ samples/plates per day

- When transfer volumes are too small to handle consistently or precisely

- When you need more reproducible outcomes

- When additional labor costs are a concern

- When the risk of repetitive stress injuries increases

- When there are safety issues regarding handling infectious or hazardous sample

- When you plan on implementing a fully automated robotic lab automation system

Evaluate Your Process

Before making any decision on the purchase of a robotic liquid handler it’s essential to evaluate the process(es) to be automated. Do you have a well-defined and robust process? Are you doing sample preparation, serial dilutions, normalizations or just some simple reagent transfers? What are the fluids and volumes to be transferred? What labware will be used? How many transfers need to be completed per hour or per day? Will the current throughput need to increase in the future? Is walk-away time important and how much. How much bench and lab space do you have? Are there any unique parameters that need to be taken into account? These are just a few of the key questions that should be defined prior to purchase and deciding how a liquid handler will integrated into your current process

Costs/Options

Today’s laboratory automation systems industry offers a wide variety of robotic liquid handler options and configurations. The costs for a liquid handler can range from as little as $5000 to over $300,000. The choice of options is numerous, such as the number of pipettes, number of pipetting, arms deck size, barcode scanning, robotic plate movers, shakers, vacuum manifolds, and the list goes on. The more features your process needs, and the higher the cost of the instrument.

Liquid Parameters/Liquid Classes

The type of liquids tested in research and analytical labs can vary greatly. Fluids tested can be as thick as molasses to a fast-flowing organic solvents such as chloroform. When pipetting these extremes by hand a person can adapt and make visual adjustments to the hand pipette. Successful liquid transfers involve knowing the type of liquid and accounting for its behavior in a particular environment. When programming automated liquid handlers you must know everything about the liquid, such as viscosity, density, surface tension, cohesion, and vapor pressure. To accommodate for these variance, automated liquid handlers’ software has settings known as liquid parameters or liquid classes. These can consist of a few key parameters (speed, air gap, delay, break off speed) to as many as 25 different settings. Some liquid handlers can automatically adjust liquid parameters on the fly (adjusting for low viscosity fluids that may drip) or notify the user of clot in a pipette tip. If you are pipetting difficult fluids or have need of some advanced feature, be sure to investigate the various liquid class parameters that the various liquid handlers offer.

Comments

Post a Comment